sheet metal welding symbols weld symbol specifies the type of weld to be applied to a part. The welding symbol is made of several parts including the reference line, arrow, and weld symbol when required. WCC Sheet Metal Works is a service oriented company engaged in cutting services and sheet metal fabrication. The pioneer in Waterjet and Fiber Laser Cutting Services in the Philippines. .

0 · weld symbols chart with examples

1 · weld symbols chart and definitions

2 · weld symbol with dotted line

3 · stitch welding symbols on drawings

4 · spot welding symbol in drawing

5 · spot weld symbols chart

6 · pipe weld symbols chart

7 · blueprint welding symbols chart

We first describe the wealth distribution by parental status and household type. For the broad categories of parents and non-parents, and for each of the more detailed household types, we estimated median wealth (adjusted for household size) and the mean percentile net worth, using SCF data from 2016 and 2019.

Welding symbols are the integral part and the basic requirements for fabrication as they provide vital information for the welding joint location, weld size (throat or leg length, depth of penetration) & length, weld type & quality .

weld symbol specifies the type of weld to be applied to a part. The welding symbol is made of several parts including the reference line, arrow, and weld symbol when required.

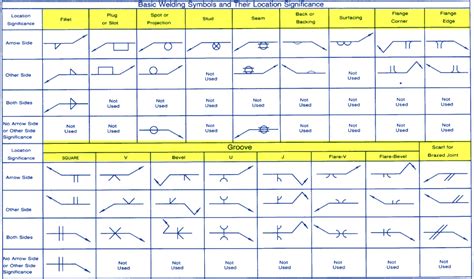

The Welding symbols are specified in the ANSI/AWS A2.4 standard. Thie standard also covers brazing and non-destructive symbols & their uses. Welding symbols for fillet, .

Name Double sided V butt Double sided bevel butt Double sided U butt weld Symbol. Name Fillet Resistance Spot Resistance Steam. Name Finish Weld Symbol on Symbol base platform . A spot weld joins two overlapping pieces of metal but doesn’t have the preparation of a plug or slot weld. You usually use them on sheet metal with a spot welding machine or a TIG welder. Like plug or spot welds, you won’t find .Understand welding symbols used in metal fabrication. Learn to interpret blueprint signs and charts for flawless project execution.What are the welding symbols, and why are they so important? Welding symbols are graphical representations used in engineering and manufacturing to communicate essential information about welds and welding processes.

Basic Weld Symbol. The weld symbol always includes 1. An arrow line 2. A reference line 3. A dashed line 4. A symbol. Note: Weld symbols on the full reference line relates to welds on the near side of the plate being welded. .Basics of Welding Symbols 21 5. Supplementary Welding Symbols 27 6. Fillet Weld Symbols 33 7. Groove Welding Symbols 45 8. Plug Weld symbols 60 9. Spot, Seam, Stud Welding Symbols 67 10. Edge Weld Symbols 77 . sheet metal industry the corner joint is used on the outer edge of the piece. This weld is a type of joint that comes together at

The edge weld symbol has many of the elements applied to other weld symbols—size, length, pitch, weld-all-around, weld-in-field, finishing and methods of finishing welds. . Sheet metal joinery uses welding metal ____ inches or less in thickness. 3/16 ____ lines may also be applied to a detail drawing to indicate lengths to be welded. If you have sheet metal CAD drawing, asses the 3D views of the design. 5. Decode Symbols and Notations. Symbols and notations indicate specific fabrication processes or requirements. These might include sheet . Weld Symbol: A small circle or dot is placed at the intersection of the reference line to indicate the location of the puddle weld. . Sheet Metal Fabrication: Puddle welds are frequently used in sheet metal fabrication to join thin metal sheets together, creating structures such as boxes, enclosures, and panels. .

The clarity and precision of CAD symbols and conventions for welding and joining are crucial in sheet metal fabrication drawings. These symbols, standardized under AWS (American Welding Society) specifications, communicate the type of weld, its size, and length, among other details, without cluttering the drawing. Precision welding methods are preferable like pulsed gas metal arc welding (GMAW-P), short-circuiting transfer gas metal arc welding (GMAW), pulsed GTAW, and gas tungsten arc welding (GTAW). Subscribe: Get FREE 30 page PDF Welding Symbols Chart With Applied Examples for Each Symbol!Mechanical Engineering solution for ConceptDraw DIAGRAM charting and drawing software is full of the pre-made examples of the mechanical drawings and stencil libraries full of the mechanical engineering-related symbols it becomes simpler to create the needed mechanical engineering drawings or assembly, parts, hydraulic and pneumatic systems’ drawings. The Mechanical . Weld symbols play a crucial role in sheet metal fabrication, enabling effective communication between designers and welders. In the UK, weld symbols adhere to specific . Read more

electrical junction box from outlet

For thin sheet metal welding it can be 30 ampere while for thicker (e.g. 1/8” square groove weld)- it can go up to 220 ampere for example. GMAW-S gives low heat and makes it easy to use in all positions on sheet metal, low carbon steel, low alloy steel, and stainless steel sheet metal from 25 gauge (0.02 inch or 0.5 mm) to 12 gauge (0.1 inches or 2.6 mm). In the production of sheet metal components, spot welding is extensively used to join metal sheets together. For example, in the manufacturing of car bodies, spot welds are applied at specific .

Welding symbols are very essential during production of your sheet metal welding drawings. The act as a way of communication between the welder and designer. Therefore, there must be sheet metal welding standards regarding information representation on your welding drawings that should relays same message irrespective of person reading.

A chart of the basic welding symbols and their location significance. A chart of the supplementary symbols. A drawing of the location of elements of a welding symbol and how to put it all together. Isometric views of basic joints identification of arrow side and other side joint examples. Typical welding symbols examples.

electrical junction box sizes

Sheet Metal and Welding Quiz. What happens to the thickness of sheet metal as you go from 8 gauge to 22 gauge? Identify 2 methods of showing sheet metal parts on a mechanical drawing. Identify 2 methods of dimensioning features on a sheet metal part. Define bend allowance and identify 3 factors that impact the amount of bend allowance presence. Weld symbols are shorthand for describing weld type, size & other processing information. These symbols indicate processes used in metal joining operations. . In the production of sheet metal components, spot welding is extensively used to join metal sheets together. For example, in the manufacturing of car bodies, spot welds are applied at .Welding Symbols that can be used when drawing sheet metal fabrications. There are occasions when simply saying weld here or corners to be welded doesn’t fully explain what may be important to you for your sheet metal fabrication design. It is used to join a wide range of metal surfaces, including sheet metal, wire mesh, and metal tubes. Spot welding is also used in the automotive industry to join body panels, frames, and other metal components. .

By utilizing the horizontal line, fillet weld symbols, groove weld symbols, spot weld symbols, and field weld symbols, as well as providing clear specifications for weld metal and weld joints, engineers, welders, and fabricators can work together .In the following example, a number of welding symbols are added to a simple sheet metal design. 8. Common Welding ProcessesCommon Welding Processes • GMAW- Gas Metal Arc Welding, sometimes call Mig uses the heat of an electric arc between a continuous bare wire filler metal electrode and the work. Shielding is obtained entirely from an externally supplied inert gas (argon or helium) or reactive gases (C02 o 02) or a combination thereof.Welding symbols, like sign posts are informational directors. They are placed on welding drawings by welding engineers and their purpose is to relay information to the welder. . When two pieces of metal, other than sheet metal or thin sections, are butted together for welding they usually have some form of a groove to allow the weld to .

weld symbols chart with examples

Weld symbols play a crucial role in sheet metal fabrication, enabling effective communication between designers and welders. . Shown as a triangle-shaped symbol, it is used to represent a weld made in the corner formed by two pieces of metal. Edge Weld: This symbol is used to represent a weld made along the edge of a joint, such as when .For additional information about welding symbols, refer to Symbols for Welding and Nondestructive Testing, ANSI/AWS A2.4-86. Information provided by Tpub.com HOME | SHEET METAL FABRICATION | INSTALLATION | WELDING | SANDBLASTING | SHIPPING & RECEIVING | INDUSTRIAL MACHINE SHOP | BUY, SELL, TRADE, RENT

Welding is a technique used in sheet metal fabrication where weld symbols are used to enable designers to communicate with coded welders by placing welding information onto drawings.. Welding Standards. EN ISO 2553:2013 is the British standard for weld symbols which provides the rules for the symbolic representation of welded, brazed and soldered joints on drawings. I am creating a water tight sheet metal box, and would like to specify on the drawing where and how to weld the edges closed. . Designing a weld joint is more than sticking a random weld symbol on a drawing. It starts with quantified requirements. Upvote 0 Downvote. Nov 26, 2014; Thread starter #9 imagineers Mechanical. Nov 2, 2010 162 CA.Basic weld symbols are used to indicate the welding processes used in metal joining operations, whether the weld is localized or “all around”, whether it is a shop or field weld, and the contour of welds . Welding Tables; Sheet Metal Brakes; Welding Carts; Propane Torches; TIG Torches; Pipe Bevellers; Metal Finishing Sanders; A welding symbol is a set of standardized graphical instructions used on blueprints to indicate where and how to perform a particular weld. Each symbol consists of several parts, including the reference line, arrow, tail, and weld symbols, which can be combined in different ways to provide detailed instructions. . Thin materials, sheet metal .

Flange weld symbols are used for lighter gauge metal joints indicating the flaring or flanging of the joint to be welded. These symbols have no arrow or side significance. . This joint type is one of the most popular in the sheet metal industry because it is easy to .

weld symbols chart and definitions

electrical junction box in ceiling

Watling Estate Conservation Area has a very diverse cultural mix and large numbers of young families and older people. There are approximately 4,000 homes on the Watling Estate comprising.

sheet metal welding symbols|pipe weld symbols chart